Siemens Opcenter: Integrated Manufacturing Operations Management (MOM) for Digital Transformation

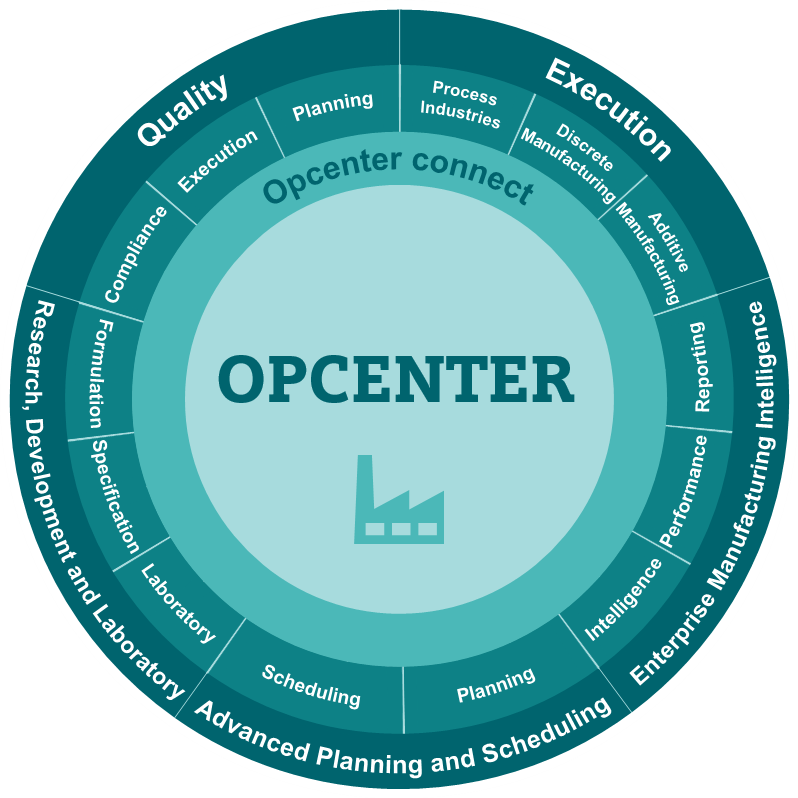

Siemens Opcenter is a comprehensive Manufacturing Operations Management (MOM) solution designed to help manufacturers achieve end-to-end visibility, control, and optimization of their production processes. Built for industries such as automotive, aerospace, electronics, consumer goods, and life sciences, Opcenter integrates production management, quality management, advanced planning and scheduling, and performance monitoring into a unified platform. This allows manufacturers to streamline their operations, ensure product quality, and accelerate their digital transformation journey.

Opcenter provides real-time monitoring and control of shop floor operations, helping manufacturers optimize production execution and improve resource utilization. It offers powerful tools for manufacturing execution system (MES) functionalities, ensuring that work orders are efficiently processed, tracked, and completed with minimal disruptions. The platform’s quality management capabilities ensure that products meet regulatory standards and customer specifications, allowing for continuous improvement and compliance.

The advanced planning and scheduling (APS) module helps businesses create accurate production schedules based on real-time data, balancing resource availability with production demands. This minimizes bottlenecks and ensures that manufacturing processes are aligned with business goals. Additionally, Opcenter Analytics provides actionable insights through real-time data collection, reporting, and analysis, allowing manufacturers to identify and address production inefficiencies quickly.

Opcenter integrates seamlessly with enterprise resource planning (ERP) systems, product lifecycle management (PLM), and other business applications, creating a holistic approach to manufacturing that bridges the gap between the shop floor and top-level business strategies.

Key Benefits:

Comprehensive MOM solution integrating MES, quality management, planning, and performance monitoring.

Real-time production monitoring and control for improved shop floor visibility and resource utilization.

Advanced planning and scheduling (APS) tools to optimize production schedules and minimize bottlenecks.

Quality management to ensure compliance with regulatory standards and continuous improvement.

Seamless integration with ERP, PLM, and other business systems for holistic manufacturing management.

Ideal for industries like automotive, aerospace, electronics, and consumer goods.

For more information, visit the official product page: Siemens Opcenter